Industry information

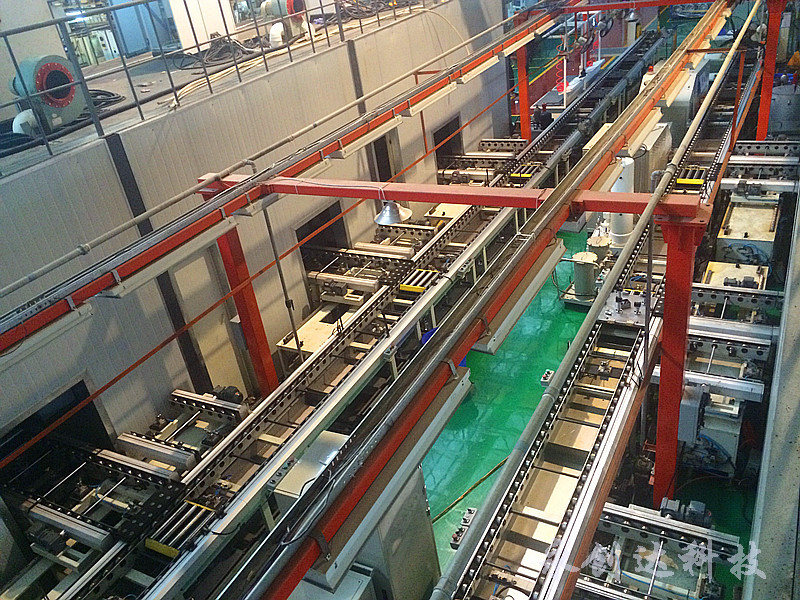

Smart Factory-Data Management System

Data collection system for equipments of the whole plant applicable to smart factory, can complete real-time collection and real-time monitoring of equipment status information and production data for its automatic production and manufacturing equipments like production line, machine vision, robot, CNC equipment, automatic control equipment, AVG trolley, and stereoscopic warehouse, by industrial field bus network, to provide accurate basic data platform for production and management system (MES/ERP/CIMS).

Advantage of System:

★ based on industrial framework 4.0, adopt connectivity technology, set up centralized collection system for equipment data and build visual smart factory.

★ based on Windows system, store all data in real-time database and historical database, set up cloud platform for industrial data, and provide accurate and reliable data source for MES.

What is Industry 4.0?

As for industrial mechanization 4.0, with steam engine as symbol, it replaces manpower with machine driven by steam power, hence separate handicraft industry from agriculture and officially enter into industry. As for industry electrification 2.0, with wide application of electric power as symbol, it replaces steam power with electrical driven machine, hence parts manufacturing separates from product assembly, and industry enters into mass production age. Regarding industry automation 3.0, with wide application of PLC (programmable logic controller) and PC as symbol, hence machine not only takes over the most part of manual labor, but also some parts of brain work at the same time. Since then, industrial capacity surpasses consumption power of mankind and mankind step into age with excess production capacity. When getting to know industry 4.0, we shall have a look at current situation and we call it industry 3.X. As described in the coatard novel, it is also the middle and later periods of 3.0, which can be understood as complete automation and partial informatization.

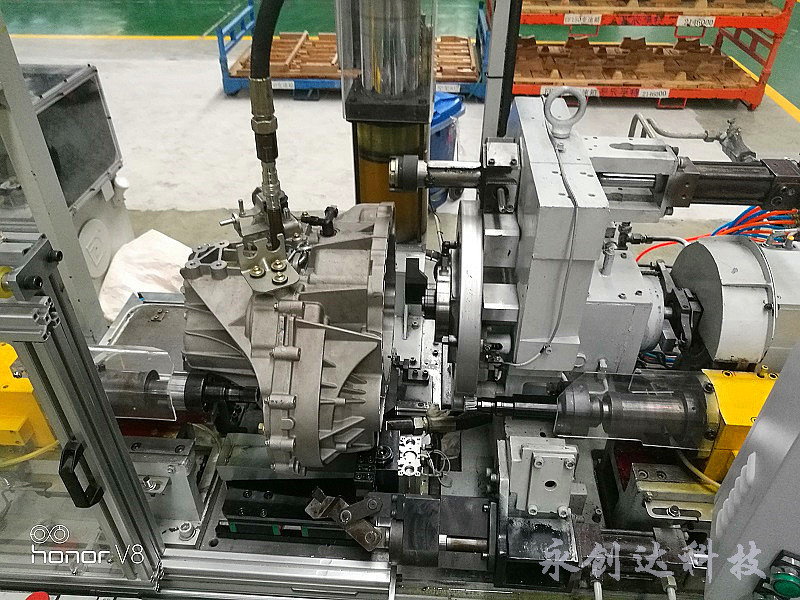

Operation Principle of AT, CVT, and DSG

It is well-known that vehicle gearbox can be divided into automatic gearbox and manual gearbox. But not everyone can completely tell varieties of automatic gearboxes and their differences in operation principle.

Next, we will make an in-depth interpretation of operation principles of automatic gearboxes including AT, CVT and DSG.

Structure and Operation Principle of Automatic Gearbox AT

At present, automatic gearbox generally has hydraulic torque converter, which is commonly known as “AT” automatic gearbox.

About us

Beijing Yongchuangda Scientific and Technological Development Co., Ltd., as high-tech enterprise in China, focuses on serving automobile, motorcycle, internal combustion engine, engineering machinery and other industries as well as fields like petrochemical engineering. Especially for automatic assembly line for automobile industry, it has accumulated rich experience in model selection and system integration of production assembly line, and has successfully applied to practical assembly production line.

Since establishment, Beijing Yongchuangda Scientific and Technological Development Co., Ltd. has been devoted to refine assembly and providing customers with the most excellent product and quality service all the time, and has gradually developed in the market competition. It respectively has branches and offices in Chengdu of Sichuan Province, Wuhan of Hubei Province, Weifang of Shandong Province and Tianjin.